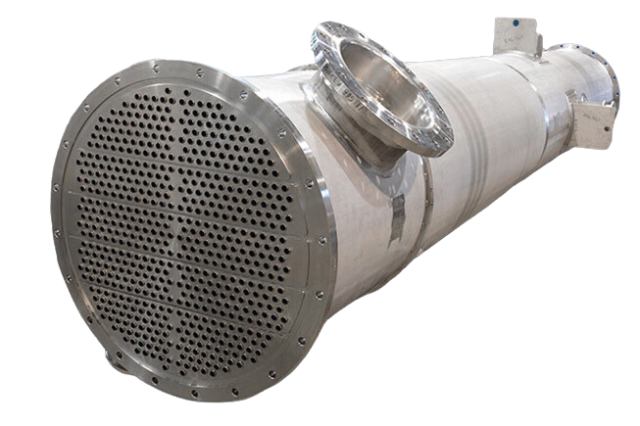

Shell & Tube

Sanitary and Utility shell & tube heat exchangers

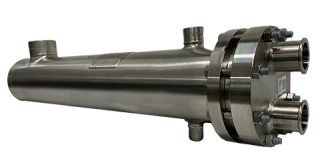

Food, Dairy & Beverage Designs

Enerquip is an industry leader in providing sanitary shell and tube heat exchangers. Their stainless-steel shell and tube heat exchangers are widely used in the food, beverage, dairy, and personal care industries. Customers have come to rely on their sanitary heat exchangers for their ruggedness and ability to meet tough regulatory obligations.

Typical Food & Dairy Processes Using Enerquip Exchangers

Typical Food & Dairy Processes Using Enerquip Exchangers

- Evaporation such as sugar concentration

- Juice, sauce, oil, soup, and syrup

- Brewery processes

- Chocolate, peanut butter, and other viscous products

- Cheese and whey products

Pharmaceutical Designs

Enerquip's heat exchangers are in use by pharmaceutical companies within the Americas and Europe in applications where cleanability and surface finish are of the utmost importance. Each exchanger is designed and constructed under one or more of the following certifications: ASME, 3-A, TEMA, PED, and BPE. A CRN (Canadian Registration Number) can be obtained for any of the Canadian provinces. Enerquip's heat exchangers meet our client's design criteria and perform as predicted.

Enerquip's pharmaceutical grade exchangers are designed with sanitary connections on the process side using USP Class VI O-rings. Materials for the O-rings are carefully selected to be compatible with process fluids. When needed, product contact surfaces may be mechanically polished to a 10 Ra finish or better and then electro-polished for maximum corrosion resistance and sanitary performance.

Typical Pharmaceutical Processes Using Enerquip Exchangers

- WFI, USP, DI, RO, or ultra-pure water

- Pure steam

- Blood, plasma, or growth media

- API or formulated pharmaceuticals

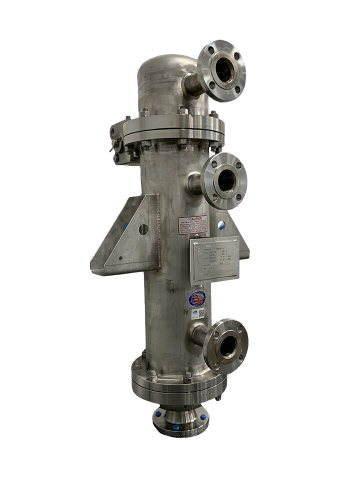

Industrial Designs

Enerquip's shell and tube designs are manufactured according to TEMA guidelines with straight tubes, or U-tubes in sizes ranging from 2" to 48" in diameter. Each heat exchanger may be built according to the requirements of the following TEMA classes:

- Class B: chemical process

- Class C: general process

- Class R: petroleum process

Although Enerquip can design ASME heat exchangers for operating pressures as high as 3,000 psig, our standard heat exchangers are usually designed for 150 psig at 375° F. Heat exchangers can also be built that meet 3-A, PED, and PBE codes. A CRN (Canadian Registration Number) can be obtained for any of the Canadian provinces. With each heat exchanger, Enerquip offers the following options:

-

- Insulation (non-asbestos and chloride free)

- Horizontal or vertical mounting supports

- Pitched to encourage draining

- Vacuum breakers

- NPT threaded connections

- Davit arms (used with heavy water box designs)

Manufacturer’s website for Shell & Tube Heat Exchangers: www.enerquip.com

Food & Beverage

Documents

- Enerquip Thermal Solutions

- Enerquip Vapor Condensers

- Enerquip Pharma-Grade Heat Exchangers

- Enerquip Custom Shell & Tube Heat Exchangers

- Enerquip OEM Custom Fabrication

For a quote or for more information about this product Request a Quote now.