UV Water Purification

![]()

Aquionics specializes in UV technology for water and wastewater disinfection, dechlorination and deozonation. Working with the biggest names in the food, beverage, electronics and pharmaceutical industries, the company has gained valuable insights into its customers’ requirements and specialized applications.

Ultraviolet (UV) technology was originally used to ensure the adequate disinfection of municipal drinking water. Since its introduction over 40 years’ ago it is now applied globally for disinfection, of water in many different industries, including food and beverage, pharmaceutical manufacturing, aquaculture, pools and leisure and shipping.

UV is effective on all known spoilage microorganisms, including bacteria, viruses, yeasts and molds (and their spores) leaving them inactive to contaminate. It is a low maintenance, environmentally friendly technology ensuring high levels of disinfection, which can eliminate the need for chemical treatment or act as the final step in a multi-barrier treatment process.

How UV disinfection works

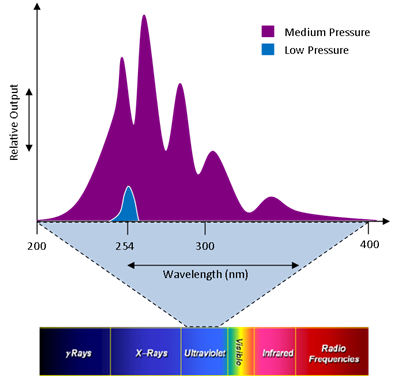

UV is the part of the electromagnetic spectrum between visible light and X-rays. The specific portion of the UV spectrum between 185-400nm (known as UV-C) has a strong germicidal effect, with peak effectiveness at 265nm. At these wavelengths UV eliminates microorganisms by penetrating their cell membranes and damaging the DNA, making them unable to reproduce and effectively killing them.

A typical UV disinfection system for process water or liquid ingredient consists of a UV lamp housed in a protective quartz sleeve and mounted within a cylindrical stainless steel chamber. The liquid to be treated enters at one end and passes along the entire length of the chamber before exiting at the other end. Virtually any liquid can be effectively treated with UV, including raw mains water, filtered process water, viscous sugar syrups, beverages and effluent.

There are no microorganisms known to be resistant to UV; this includes pathogenic bacteria such as Listeria, Legionella and Cryptosporidium (and its spores, which are resistant to chlorination).

UV technologies

There are two main types of UV technology based on the UV lamps used: low pressure and medium pressure. Low pressure lamps have a ‘monochromatic’ UV output (limited to a single wavelength at 254nm), whereas medium pressure lamps have a ‘polychromatic’ UV output (between 185-400nm).

As UV has no residual effect, the best position for a treatment system is immediately prior to the point of use. This ensures incoming microbiological contaminants are destroyed and there is a minimal chance of post-treatment contamination.

UV Applications

Food, beverage, and brewing industries

Aquionics product: PureLine UV

-

Disinfection of direct contact water

-

CIP (Clean-in-Place) rinse water

-

Filter disinfection

-

Cooling media and chiller disinfection (Brine)

-

Sugar syrups

-

De-aerated liquor

-

Yeast preparation

-

Waste water (Re-use)

Pharmaceutical industry

Aquionics product: PharmaLine UV

-

Disinfection of direct contact water

-

Filter disinfection

-

TOC Reduction

-

Dechlorination

-

Waste water (Re-use)

Validated Systems –Performance Qualified (PQ):

-

FDA PMO compliant systems for the dairy industry

-

NWRI validated systems for water re-use

-

3rd party validated for guaranteed performance across an array of organisms

Documents

- PharmaLine DL Data Sheet

- PharmaLine DO Data Sheet

- PharmaLine DP Data Sheet

- PharmaLine PQ Data Sheet

- PureLine B Data Sheet

- PureLine D Data Sheet

- PureLine DO Data Sheet

- PureLine PQ Data Sheet

- PureLine S Data Sheet

For a quote or for more information about this product Request a Quote now.